Rising demand,

sophisticated solutions

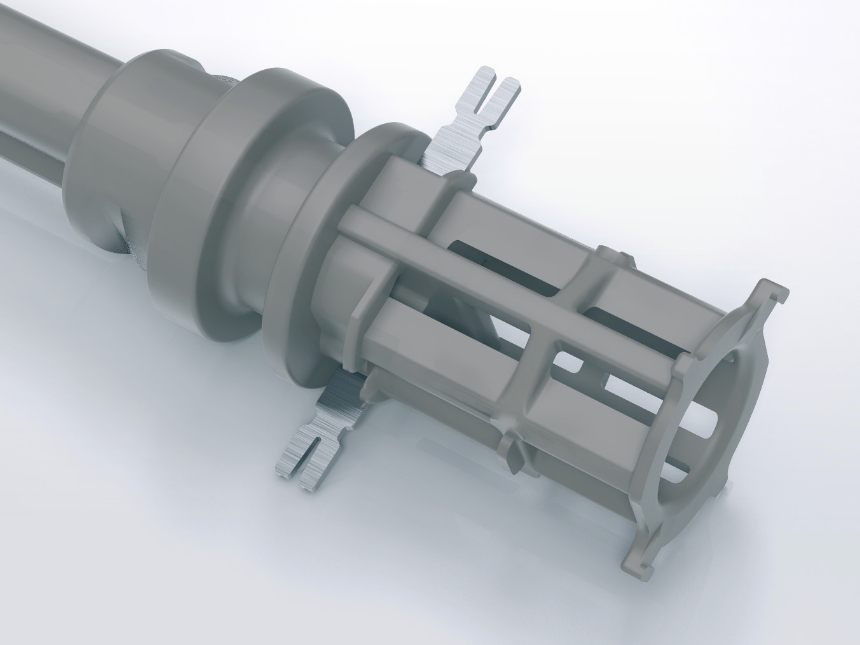

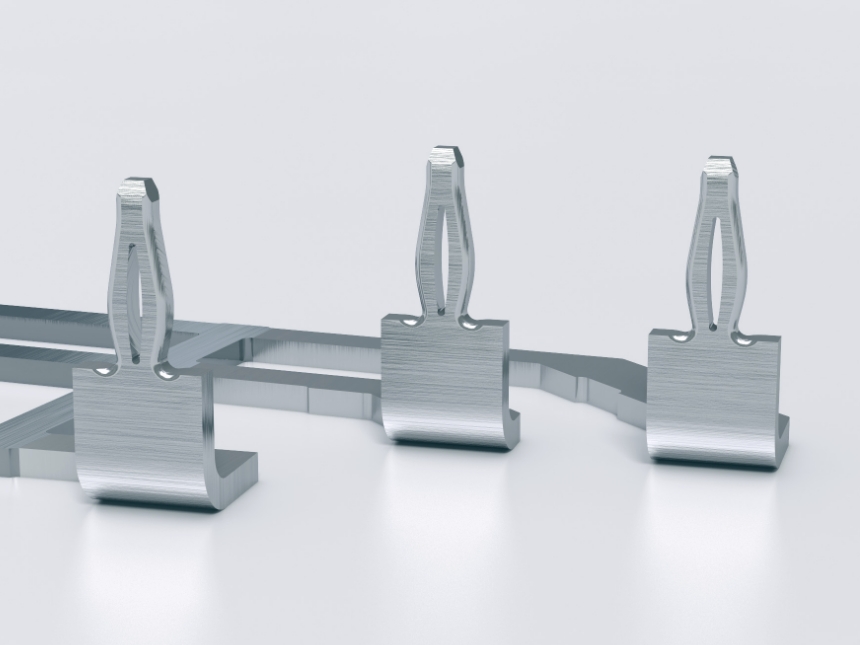

Overmolding inserts is one of the frequent tasks that we regularly solve to the satisfaction of our customers. The so-called hybrid technology is extended by a sophisticated dimension when components are to be processed in such a way that a tight connection is created with respect to the external medium. The experts at Nesper also find economical and reliable solutions for this task. For example, an oil level sensor can be realized by first coating wires with a special lacquer. In the subsequent overmoulding process, the coating bonds with the liquid plastic and creates a connection that is impermeable to the external medium, oil. Especially in the field of sensor technology, for example in the automotive sector, such a media-tight bond is increasingly in demand. Nesper also offers individual solutions for increasingly complex components on state-of-the-art machines – from developing the best process and selecting the right material to cost-effective series production.